0:11

hello everyone welcome to automation

0:14

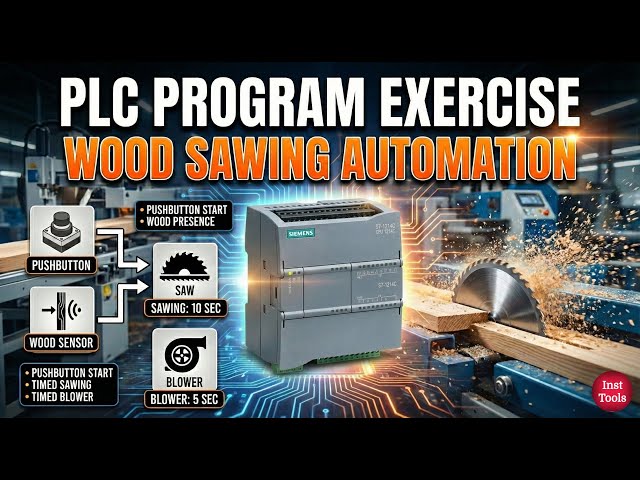

Community today in this video we are

0:17

going to discuss an example which will

0:19

be about wood sowing so let's look at

0:22

the example first wood sowing the sawing

0:26

operation takes place for 10 seconds

0:29

when push button is pressed and wood is

0:31

placed there after sawing is complete

0:34

the wood is removed and a blower is used

0:36

to blow away the saw dust which remains

0:41

seconds that means we have a start

0:44

button that being pressed and sensor

0:47

being activat the sensor will activate

0:49

only when the board is being placed

0:51

there so the sewing operation will start

0:54

for 10 seconds and after that when

0:56

sensor gets deactivated the fan will

0:59

turn turn on for 5 seconds blowing away

1:02

do does for 5 seconds so for this

1:05

example we will use normally open

1:07

contacts as well as normally close

1:09

contacts with that we will be also using

1:11

some memory bits and timers like TP so

1:15

let's move to TI portal where we will

1:17

draw a ladder diagram for this

1:21

example this is the interface of TI

1:23

portal version 16 so firstly we will go

1:26

to here and double click on plc tags and

1:30

default tag table so here we need to add

1:33

our inputs and outputs so the first

1:35

input is start button and then we have

1:38

one more input that is the

1:41

sensor sensor and then we have an output

1:47

saw it is an output so its address will

1:50

be Q 0.0 and then we have one more

1:54

output that is the fan that will blow

1:56

away the dust and after that I will

1:58

double click on program blocks and then

2:02

ob1 so here we will draw the ladder

2:05

diagram so firstly I will insert a

2:07

normally open contact for the start

2:09

button and a coil so this uh normally

2:13

open contact will be the start button

2:17

and the co the coil will represent a

2:19

memory bit so let's say m

2:22

0.0 and after that we add it here so I

2:25

will add a normally open contact sorry I

2:27

will open the branch add a normally open

2:29

contact and close the bran so this will

2:33

0.0 and after that this m 0.0 will be

2:36

used here as normally open contact it

2:39

get activated when start button is being

2:41

pressed and then we'll use one more

2:43

normally open contact that will

2:45

represent the sensor so I will select

2:49

sensor from the list and then I will

2:51

insert a coil that will represent the

2:54

saw so the sawing operation will start

2:57

when M 0.0 gets through and the sensor

3:00

gets activated M 0.0 gets through when

3:02

start button is being pressed so this

3:04

sawing process operation will be for a

3:07

definite period of time and it will be

3:09

for 10 seconds for that we will use a

3:11

timer operation that is a

3:13

TP and the preset value will be 10

3:20

seconds and after that we'll use the

3:23

swing operation here as normally open

3:40

and then add a coil and this coil will

3:44

represent a memory bit so this will be M

3:47

0.1 and we will L this here so I will

3:50

add a normally open contact sorry I will

3:52

open the branch at a normally open

3:54

contact and then close so this will be M

3:58

0.1 and then this m 0.1 will be used

4:04

here as normally open contact so this

4:09

0.1 and here we will use one more

4:12

normally open contact that is M

4:19

then we will use a normally closed

4:22

contact for the sensor so I will insert

4:25

a normally closed contact for the sensor

4:28

that means when the wood is not

4:31

there when the wood is being taken away

4:34

the sensor gets deactivated the current

4:36

will flow through this and as a result

4:40

on there will be fan which will

4:45

work for 5 seconds for that we'll use a

4:55

okay and this fan will be

5:01

the pret value will be 5

5:06

seconds so when start button is being

5:08

pressed and released this m 0.0 gets

5:10

through when it gets through the sewing

5:12

machine will operate only if the wood is

5:15

being placed there the sensor gets

5:16

activated and the sewing process will

5:18

start and it will saw the uh V for 10

5:21

seconds so after that when sewing is

5:24

gets activated this m 0.1 gets through

5:26

it shows the data that sowing was was

5:29

done and when it is activated and start

5:32

button was being pressed and the sensor

5:34

gets deactivated that means wooding be

5:37

wood is being uh taken from that there

5:42

so the fan will activate for 5 seconds

5:44

and it will blow away the dust on the

5:46

machine so we'll start the simulation

7:20

finish after that I will start the

7:25

CPU and start monitoring

7:31

and then sech to project

7:32

view here we need to create a new

7:35

project in the project view let's press

8:02

I will press contrl n to create a new

8:07

project click on Create and then

10:21

here and double click on simulation

10:24

tables and then simulation table one

10:32

here and click on load project

10:37

TXS so when start button is being

10:44

released this m 0.0 gets through and

10:47

this m 0.0 allows the current to flow

10:50

through this but the sewing operation

10:52

has not started yet so the sensor should

10:54

be activator so for that the wood is

10:57

being placed there the sensor gets AC

10:59

Ator as you can see the sawing operation

11:02

has started and it will saw for 10

11:06

seconds and after 10 seconds the sewing

11:09

operation will uh will stop but this m

11:12

0.1 gets through and when it gets

11:15

through the fan should get on but the

11:17

sensor should be deactivated that means

11:19

the wood uh has to be taken from there

11:22

the when sensor get deactivated the fan

11:24

will blow away the dust from it for 5

11:27

seconds and after 5 Seconds the fan will

11:29

stop it was all about this example thank