0:14

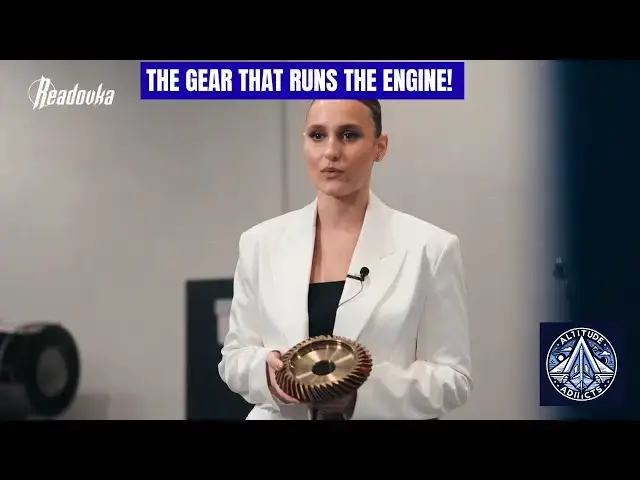

When we talk about the engine in the

0:16

head, there is an image of large loud

0:18

parts, powerful turbine compressors. But

0:21

there is among them Sophie's presence.

0:23

We don't notice small modest. This is a

0:27

gear like this. But try to remove it and

0:29

the whole engine will go silent because

0:31

it is the gear that connects the

0:33

mechanism and allows all these steel

0:36

giants to work as one in this geometry.

0:38

The power, the precision and the meaning

0:41

of the whole system. Today we will find

0:45

why is this detail invisible to the eye,

0:48

the heart of the movement.

0:55

But this is only at a glance now. It

0:57

seems so simple because here we look and

1:00

everything seems easy and simple to us

1:02

at a glance but in fact it is far from

1:04

so simple because the modern development

1:06

of our moose and that is where our

1:08

science and mechanical engineering

1:10

allows us to lay very complex geometry

1:13

in the tooth wine itself. The level of

1:16

machine tool construction that exists

1:18

today allows this whole very complex

1:20

geometry to be embodied directly in

1:22

microns or even more than 10 microns.

1:25

Not all testers are responsible and

1:28

unique in the form. There are gears that

1:29

are simple workers. Although it is

1:31

probably still correct to say that in an

1:33

aircraft engine every detail, yes, it is

1:36

responsible. It is necessary. It has a

1:39

certain functionality. But

1:42

there are gears that simple workers are

1:45

ordinary simple to gear. But raised

1:48

points, they do not bear high load and

1:50

they are mainly used in outboard boxes

1:53

of units. For example, they don't have

1:55

any pump or rotation sensors. That's it.

2:01

The loads that other gears experience,

2:03

these are what we call the most which

2:05

are the most responsible manufacturers

2:07

which are responsible for the overall

2:10

reliability and operation of the entire

2:12

engine are the central bevel gear.

2:16

These are those gears that rotate at the

2:19

same speeds, experience almost the same

2:21

loads as the engine rotor itself. This

2:24

is the work of the Swift. We say that

2:26

they are the most they are the most

2:27

responsible. They have the highest

2:29

manufacturing requirements which are

2:34

somewhere even dozens. Next is micron.

2:37

And these are the same interesting

3:05

So, we figured out why a gear has

3:07

perfect geometry, but it's not born

3:09

perfect. Each tooth goes a long way from

3:11

rough metal to perfect shape. First,

3:13

there is rough processing. At this

3:15

stage, the metal first acquires the

3:17

consoles of the future part. Then heat

3:20

treatment of the metal strengthens,

3:22

hardens, and makes stable loads that

3:24

will experience 1,000 hours of work.

3:30

And finally, frequency processing is

3:32

practically a jewel stage where every

3:34

micron of shavings is a step towards the

3:36

efficient operation of the entire

3:39

But even the perfect gear is only half

3:41

the story because she has a partner and

3:44

together about her the perfect furry

3:52

Well, any six I have is a park in

3:54

Russia. That is any blank is some kind

3:56

of cylindrical blank. Yes, if we allow

4:01

or is it some kind of ring blank?

4:03

Therefore the main machining in general

4:05

is more precisely or all the processing

4:07

that is associated with the processing

4:09

of poly. This is rough turning. The

4:11

maximum removal of material is a blank.

4:14

Then heat treatment occurs which after

4:16

rough turning will lay down the basic

4:18

properties of the material which are

4:20

reported in the design documentation.

4:25

After this preliminary such basic heat

4:27

treatment is performed.

4:30

The halfhour processing which will

4:32

include various stages is embodied in

4:34

the drawing. These are various groups.

4:37

Half hour turning, preliminary turning,

4:39

then depending on the design, a

4:42

strengthening heat treatment can be

4:44

carried out which provides a high

4:46

hardness of the profile surface and then

4:48

the final treatment is already taking

4:53

Blinding this is considered a finishing

4:56

tennis treatment. 60% of all success in

4:59

the manufacturer of gears is heat

5:03

During heat treatment, the basic

5:05

properties materials that start the

5:07

design documentation are laid and high

5:10

hardness of the gear profile is also

5:13

ensured. If the heat treatment is

5:15

performed incorrectly or with a

5:17

deviation, it will no longer be possible

5:21

This will be considered however the

5:23

remaining 40% let's say this is the

5:26

finishing treatment of the blindness

5:28

operation which provides these very

5:30

micron and this is the accuracy that

5:33

lies in the documentation in the end

5:42

rough processing as I said yes this is

5:45

the processing in which the maximum

5:47

material is removed yes from the surface

5:49

of the work piece After rough

5:51

processing, the part acquires just

5:54

outlines or counters. What we see is the

5:57

drawings of frequent processing. Without

5:59

changing the outline of the part, the

6:01

part acquires its final shape the

6:03

geometric appearance that we see in the

6:05

design documentation.

6:07

Well, you can even give a clear example.

6:09

Yes, what is the difference between

6:10

rough processing and finishing? If we

6:12

need, for example, to paint a large wall

6:14

over the area, yes, we will most likely

6:17

choose some kind of broad script or

6:18

varia. Yes. What if we need to draw some

6:21

ornament or pattern? We will rather

6:23

choose the piston in the same way when

6:25

processing the session. Yes, of course,

6:28

you can starting from the work piece

6:30

produce it and grind it in the same way.

6:32

For example, on a lathe, try to catch

6:34

this micron. Yes, it's all the same, but

6:37

it's with a thin brush. Yes. Or a

6:40

roller. This is our tears. This is our

6:44

time. This is our nerve because it will

6:46

be very long through mechanical

6:49

engineering. This is called the economic

6:51

efficiency of processing or let's say

6:54

the labor intensity of manufacturing

6:56

part if it is very long in time and

6:59

takes away the strength of the worker.

7:00

Then the part will cost like painting

7:03

from the louver and such a product at

7:05

such a cost will be unprofitable and no

7:08

one will have a laptop.

7:18

The uniqueness of our gears, you their

7:21

identity. Each of those processes is

7:23

worked out and honed. Thanks to this, we

7:25

guarantee high reliability and close to

7:34

The highest accuracy is needed not only

7:36

for the sake of engine life. When the

7:38

six does not work, vibration is

7:40

perfectly reduced. And the less

7:41

vibration, the less noise, which means

7:43

the whole system works quieter and more

7:45

environmentally friendly.

7:54

Quality is formed from the system that

7:56

is implemented in the factory. Yes, this

7:59

system does not press quality. Control

8:02

is carried out from the purchase of

8:03

metal and ending at all stages of its

8:10

In the search accuracy regulated

8:13

precisely by the industry standards of

8:15

our aviation engineering, the designer

8:17

depending on the working conditions and

8:19

purpose of his gears precisely assigns

8:22

the degree of accuracy. Each degree of

8:24

accuracy is characterized by three

8:26

indicators. This is the norm of

8:27

kinematic accuracy. The standard of

8:30

tooth contact accuracy and the standard

8:33

of smoothness of operation. Each such

8:35

accuracy consists of certain complexity

8:38

and this is exactly what constitutes the

8:40

accuracy of the gear wheel.

8:46

An aircraft engine is a very highly

8:48

responsible product. In general, high

8:51

requirements are placed on it regarding

8:53

the strength reserve. So let's assume of

8:55

course that this is not a deviation.

8:57

This deviation from the design

8:59

documentation is correct. To do this you

9:01

will need to file a request for

9:03

rejection. The designer may perform some

9:06

calculations and make a final decision.

9:09

Is it possible to allow such a detail

9:13

for the product or impossible?

9:15

For instance, a few microns deviation

9:17

might be permissible.

9:19

It is possible that there will be some

9:21

noise and it is possible that the

9:23

uniformity of load distribution in the

9:25

pair of gears will shift. But again, I

9:28

repeat, nothing can happen. Here's for

9:30

our understanding. Most likely in case

9:33

of any defect or repair of the engine,

9:35

this gear which has a deviation but was

9:38

allowed for assembly will simply be

9:40

forcibly removed from operation since it

9:43

has some deviation. Well, a certain

9:45

number of hours which will be the record

9:50

If it functions, no issues should occur.

9:59

The most special thing is when you come

10:01

to the air show with children and when

10:04

your children say your dad did it, you

10:06

are happy and enjoy that everything is

10:12

The key is because I have something new

10:14

every day. Every day is a challenge

10:16

either production or technological

10:18

documentation or some new product

10:20

development that is every day is new and

10:40

From a cold workpiece to a unique pair

10:42

operating inside a massive engine, we've

10:45

completed the journey.

10:47

Every micron, every step, every check is

10:50

the contribution of hundreds of people.

10:52

But our part will take its place at the

10:54

heart of the engine and go straight to