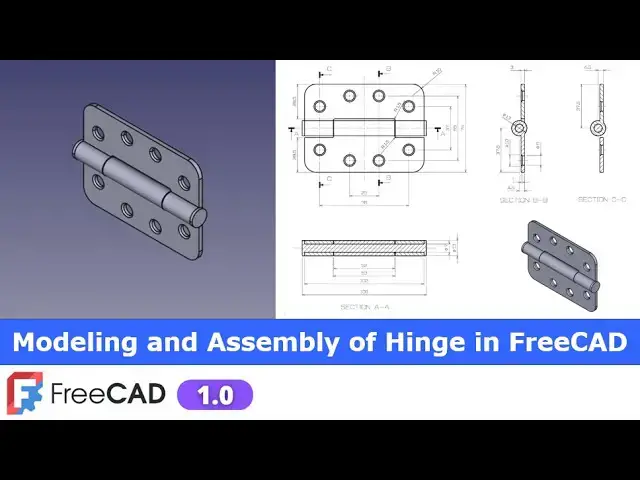

Modeling Assembly of Hinge in FreeCAD | FreeCAD Tutorial | FreeCAD Assembly | Mechnexus |

Dec 31, 2024

#freecad #freecadtutorial #freecadpartdesign

In this video I have explained How to Model Part in FreeCAD with the help of part design Workbench.

▶️ Visit my website for more info on FreeCAD-:

https://mechnexus.com/

▶️ Get my FreeCAD Crash Course for beginner-:

https://www.udemy.com/course/freecad-course-for-beginner/?referralCode=3BA9B526A12F96295D44

▶️ Download Source File of Tutorial-:

https://mechnexus.com/mechnexus-youtube-tutorial-source-file/

▶️ Become my Patron on-:

https://www.patreon.com/c/mechnexus/membership

▶️ Buy Me a Coffee

I am very grateful that you watch my videos and I am constantly trying to improve the quality of the videos on this channel. If you'd like to help me do this, please consider supporting me so that I can to continue to produce content for your enjoyment.

👉 Help support this channel by buying me a coffee: https://ko-fi.com/mechnexus

Show More Show Less View Video Transcript

0:00

Hello friends welcome to Free tutorial

0:02

and in this tutorial we will do modeling

0:05

and assembly of this H as you can see

0:08

that uh I have a model it and I have

0:12

assembled it and you can see that uh my

0:16

isometric view is matching with my

0:18

drawing isometric view so we will uh

0:22

create this assembly with the help of a

0:25

default assembly

0:27

workbench so this is is the very simple

0:30

tutorial to understand the assembly

0:34

workbench of a free care so I will close

0:37

this file and uh create a new

0:40

file you can also visit my website Mech

0:43

nexus.com where I write articles and

0:46

tutorials on freead you can download my

0:50

tutorial source file from here tutorial

0:53

source file page and you can also

0:56

support me by buying a cup of coffee on

1:01

kofi.com your uh small support will help

1:05

these channels to grow and it will

1:07

motivate me to create more awesome

1:09

content on fread I thanks to all my

1:13

supporter those who have supported me by

1:16

buying a cup of

1:18

coffee so keep supporting and uh it will

1:22

help me to grow this Channel and it will

1:26

motivate me to create more awesome and

1:29

useful full tutorials on freeat so let's

1:32

come back to our tutorial so first I

1:36

will create a new file and now I will uh

1:40

insert my body and I will on my origin

1:43

plane so now so if we zoom out so we can

1:49

see that uh these two hints are

1:52

assembled with the help of a pin and we

1:55

can see the details in the section view

1:58

now uh first thing which I will do is to

2:02

create this

2:04

body and we will save as this body and

2:07

we will make the body of other

2:10

sides so let's start our

2:13

tutorial so first I will select the

2:16

right

2:19

plane and click on the

2:22

sketch and I will off the origin

2:26

plane now on the right plane we will

2:29

switch to the side view and uh we can

2:32

find the details

2:35

here

2:37

so here is of diameter 13 and if you go

2:42

in a section view so here is a diameter

2:46

7 so I will create a circle

2:50

here and select smart Dimension and

2:54

provide it uh 13

2:58

mm and now

3:01

here I will create a

3:11

rectangle this will be the r

3:15

rectangle and now I will uh delete this

3:20

line and click on the

3:24

trim and trim

3:27

this this and this is and now we will

3:32

give the dimension so if we Zoom it we

3:35

can see the dimensions here so from

3:38

Center to this Edge is a

3:40

4.5 so I will select a

3:45

dimension and provide it

3:51

4.5 and I will move

3:54

it and here from Center to this age is

3:59

of 30

4:00

7.5 so I will select this and this and

4:05

provide it uh

4:08

37.5 and

4:10

here this is the 4.5 and the thickness

4:14

is of 3 mm so I will select it and uh

4:20

provide the 3 mm

4:22

now I will uh close

4:26

it and we will extrude it so to get

4:30

Extrusion

4:32

distance we will move to the section

4:34

view so Extrusion distance we can uh see

4:38

here is of 102 so I will select the

4:42

sketch click on

4:43

extrude and give the

4:47

102 and here I will uh keep it symmetric

4:51

to the plane and uh click on

4:53

okay

4:57

now we will uh remove the material on

5:01

this side but we will do at uh end

5:05

because I will save this part and uh

5:09

that will be helps to model the hinge of

5:13

the other side so here I will give these

5:16

two fillets so we will find out the

5:19

fillet details so it is a r10 fillet of

5:22

a typical type which means all four

5:25

corners having the r10

5:27

fets now I will select the fet tool and

5:32

uh select this

5:35

hede and uh this

5:40

hede and give the value

5:44

R1 and uh click on

5:50

okay now our uh next feature is to

5:54

create this counter s hole whose detail

5:58

is given here it is a Dia 8o through and

6:03

this diameter 10 and with depth of a 1

6:07

mm so I will switch to the front view

6:10

and uh select this pH and click on the

6:14

sketch and I rotate my

6:17

model and uh I will switch to the main

6:21

View and here are the four

6:23

holes so I will select a circle

6:27

tool create a tool circles and I will

6:31

provide the symmetricity

6:35

constraint and a distance is of

6:38

25 so I will select this and this and uh

6:43

provide the distance 25 and this is of 8

6:49

mm and select this and this and made it

6:54

equal click on the project geometry and

6:58

I will project it

7:00

so now if we move to the side view

7:05

so this is given the

7:08

55 so we will switch to the

7:14

wireframe wireframe

7:17

and here it is given a 55 which means

7:21

that

7:22

uh from the age it will be the 10

7:27

mm so select the smart dimension

7:32

iion 10

7:35

mm and

7:38

now here are the two

7:41

holes so I will uh

7:45

create the two

7:47

circles and uh make it

7:54

symmetric and now view the dimension of

7:57

76

8:00

select this and

8:02

this give the dimension

8:05

76 now we will constrain this ho so we

8:09

will select the dimension tool and

8:11

provide vertical dimensions and now here

8:14

we will uh link the

8:16

equations which is I will create a

8:20

bracket give it a

8:22

75 -

8:24

37 close the bracket divide by 2 so it

8:28

will calculate

8:30

distance and now I will close it so

8:33

here I will create a counter Sun hole so

8:37

select the whole tool and here is my

8:40

drill size of 8 mm and I will say it

8:43

through all and from here I will select

8:46

the counter sunk and the diameter is of

8:50

uh 10

8:53

mm with a depth of 1 mm

8:57

[Applause]

9:03

so click on okay

9:06

now we have created the hole now we will

9:10

create a cut so here Dimension is given

9:14

52 and 53 so this is the 52 and other

9:19

side is a 53 and there is a. 5.5 mm

9:23

clearance on the both the sides so I

9:25

will select this pH and click on the

9:28

sketch and I rotate my model and I will

9:33

switch to the wireframe

9:36

view

9:37

now I will simply create a rectangle and

9:42

I will project this Outer Edge click on

9:45

the project project it and uh select

9:49

this point and line and add a

9:53

coincidence and select the dimension

9:55

tool and uh provide it uh to

10:01

6 and I will also project this bottom

10:05

ede because position is given

10:09

29.5 click

10:12

it and select

10:15

Dimension and provide it

10:20

29.5 and set the vertical Dimension

10:23

rough set it 30 click on

10:27

close and now

10:32

will switch to the flat

10:34

lines so here I will remove the material

10:38

completely so select this page click on

10:40

the

10:41

cut say it through all and symmetric to

10:45

the plane click on okay and now select

10:49

this cut and uh mirror it on the other

10:53

side so click on the mirror tool and

10:56

from here I will select my reference

10:59

select this mid plane and click on okay

11:03

and now here is a drill of 7 mm so I

11:07

will select the phase and uh click on

11:09

the

11:10

sketch and uh create a

11:13

circle select

11:16

Dimension give the value 7 mm click on

11:20

close and uh click on the whole

11:24

tool give the 7 mm and say it through

11:28

all

11:29

say okay now if you see our drawing

11:33

there is a fillet of

11:35

r1.5 so select the fillet tool

11:41

and select this

11:44

age and uh this age and give it uh

11:51

1.5 and click on

11:54

okay so this is how we have a

12:00

made this bottom hinge let's save it and

12:05

I will uh save it uh as

12:09

R1 click on Save and now to save our

12:14

time we will save this part and we will

12:18

create the other hinge because the whole

12:21

positioning in the same and size is also

12:25

same all we have to modify this cut so I

12:29

will go to the file and click on the

12:31

save as and I will give it a part 0

12:37

to

12:42

R1 now I will uh close it and open my

12:46

fresh

12:50

part so here is my part

12:53

two now here I will delete this fillet

13:01

and delete this mirror and

13:08

cut and here we have the sketch and uh

13:12

we will edit this

13:15

sketch and uh remove this 26

13:19

dimensions

13:21

and or better to delete this sketch as

13:25

well and create a fresh sketch for the

13:29

cut so select the ph and uh click on the

13:33

sketch and now rotate my

13:36

model and uh I will create a rectangle

13:41

and uh here we will switch to the

13:46

wireframe and

13:48

now here is a dimension 53 so first I

13:53

will make this and this symmetric with

13:56

my

13:57

Axis and I will give the dimension uh

14:02

53 and

14:04

now here is a dimension is a

14:08

29.5 so I will select it and project

14:14

this age so that I can give the

14:18

dimension now select this

14:22

and and give the

14:25

29.5 and this vertical I will give the

14:29

Dimension because I wanted to remove the

14:32

material now I will switch to the flat

14:36

lines and here I will completely remove

14:39

the material select the cut and from

14:43

here say it through all and set it

14:45

symmetric to the plane and click on okay

14:53

now we will uh check the features so we

14:56

have fillet we have holes we have this

14:59

these holes so we will uh change the end

15:02

condition of this

15:05

hole so it

15:07

is failing so we will

15:11

uh delete it because it is not going

15:14

through all if I see the whole or uh

15:22

simply through all it is not detecting

15:24

here so why not delete the

15:29

this

15:38

hole and here I will on this pocket so

15:43

it was created on this phas so best

15:46

thing which we can do is to redefine the

15:50

sketch plane so we will go to our sketch

15:54

and uh go to the our uh attachment

15:57

editor

16:00

and here we will on our

16:04

body and here the attachment editor I

16:07

will delete it and select this face

16:10

again and click on

16:14

okay and let's on our whole

16:18

sketch

16:20

and edit the whole

16:29

let's select the

16:34

reverse and let's

16:37

give uh total is uh let's give the

16:42

120

16:44

okay now I will on this pocket and let's

16:49

see what

16:51

happened so here we have to

17:00

it is better

17:07

to so we have created the sketch and now

17:11

we will uh create a hole so we will uh

17:13

select the phase and click on the

17:16

sketch rotate our

17:19

model

17:23

and select the

17:25

circle and select the diameter

17:29

give it 7 mm click on close select the

17:33

whole

17:35

visard and this is of 7

17:39

mm and make it through

17:42

all click on okay

17:47

now here is a fillet of r1.5 so I will

17:51

select

17:52

this and uh this and click on the fillet

17:57

and give it to one

18:00

.5 click on

18:03

okay so we have created both the hinge

18:06

and

18:08

now we will uh create this pin so I will

18:13

create a new file create a body and on

18:16

my origin plane and here creation of

18:19

this pin is very simple if we Zoom to

18:23

this uh section view so we will simply

18:26

select the front plane and click on the

18:28

SC sketch go to the model Tab and hide

18:32

the origin so here I will uh simply

18:35

create a rectangle and now I will select

18:39

the

18:40

polyline select this vertical horizontal

18:44

and

18:44

vertical and

18:46

here I will make it vertical and this

18:50

one

18:51

uh

18:53

vertical and we do not require this line

18:56

so we will uh simply

18:59

trimit and now we will make this pin

19:03

symmetric to this axis so I will uh

19:07

click on the symmetricity constraints

19:09

like this point this point and this

19:11

axis

19:13

similarly this point this point and this

19:18

axis so select the horizontal Dimension

19:21

provide the

19:23

106 and uh this one is of 102

19:31

102 and uh this is the diameter 7 so

19:35

from this point to this point it will be

19:40

3.5 and select this to this which is of

19:45

13 / 2 so 6.5 is radius now I will move

19:51

this

19:52

Dimension and here I will provide the

19:56

horizontal constraint

20:08

so here it is

20:12

uh not updating okay now it become

20:16

horizontal now I will uh close it and

20:21

create a simple Revol and I will select

20:24

my reference this uh xais click on okay

20:29

now I will uh save my pin as a part

20:33

three so part 03 I have already modeled

20:37

it so I will give the revision

20:41

R1 so we have created all three parts

20:44

now we will create a assembly so here I

20:48

will create a new file and from here I

20:52

will switch to the assembly

20:54

workbench and create an

20:57

assembly and this is active you can

21:00

check it active object and now I will

21:03

insert my body click on open file so

21:07

here the first I will insert it my part

21:11

one say insert and now select the

21:16

body so first save your file so let's

21:20

save it so hinge assembly I will uh VI

21:23

it

21:25

R1 and uh I will say yes

21:29

click on okay now I will again insert

21:32

the same

21:34

body uh it is a same but cut is

21:36

different which is having the different

21:38

name so I will insert

21:42

the part two or 2

21:46

R1 and select

21:48

it and click on okay

21:52

now

21:54

here I can give my

21:57

name let's uh press f2 and give it a

22:01

hinge

22:05

bottom and this one is of a Hing

22:10

stop and now select the second one and

22:14

uh click on the

22:18

transform and uh we will rotate it

22:24

so this will be like this as for our

22:29

drawing now click on okay we will uh set

22:33

the hinge position if you see in the

22:35

Right

22:36

View so we have to make this face of my

22:41

top hinge and bottom hinge should be

22:43

parallel so I will select this face and

22:47

this pH and give the distance

22:51

constraint and here I have provided

22:55

distance zero and click on okay and

23:00

now I will select my top

23:07

hinge and go to the transform tool and

23:10

uh move

23:15

it okay

23:18

now I will select uh assembly and

23:22

activate it and select

23:25

this inner diameter and uh this inner

23:32

diameter and add the cylindrical

23:36

joints click on okay and now here you

23:41

can see that this and this are the

23:43

parallel and

23:45

now I

23:47

will move my top

23:51

hinge and provide the5 mm

23:56

clearance so I will select uh this

24:00

phas and this

24:04

phas and

24:06

uh first activate

24:10

it so this pH will match with this pH

24:14

with5 mm clearance so here is a distance

24:19

joint and here I will give the

24:23

0.5 I click on okay so now if you see

24:28

the right Right

24:29

View so this and this face are the

24:35

parallel so this is how we have a model

24:39

and assemble the hinge and

24:42

now we will insert the pin so we will go

24:45

to the object and uh select this pin and

24:51

click on okay so you can see that uh pin

24:54

has been placed as exact locations I can

24:58

provide the constraint okay to the my

25:02

pin or I can simply place it at a ground

25:07

so instead of providing the constraint

25:10

it is uh fit at correct locations so I

25:14

will make it ground else I can provide

25:16

the constraint

25:18

so this is how we have a model and

25:23

assemble the hinge in a free cat and uh

25:27

we have also learn the modeling with use

25:30

of assembly default workbench so this is

25:34

all about this tutorial thank you for

25:36

watching and thank you for your valuable

25:57

time for

#CAD & CAM