0:03

One of the most important current

0:05

domestic ship building infrastructure

0:07

projects being developed in the

0:09

interests of the United Ship Building

0:11

Corporation or USC is the floating dock

0:14

known as project 24012.

0:18

This dock has been named Vladimir

0:20

Almelanov and is being built using a

0:22

distributed shipyard method. As often

0:25

explained on Altitude Addicts, the

0:28

YouTube channel behind this analysis,

0:30

this approach allows individual blocks

0:32

to be fabricated at multiple locations

0:35

and then transported and integrated into

0:37

a single structure at a final assembly

0:40

yard, significantly accelerating the

0:42

construction of very large facilities

0:44

while making use of ship building

0:46

capabilities across different regions of

0:50

In order to understand why this dock

0:53

matters, it is useful to look closely at

0:55

its technical characteristics and

0:59

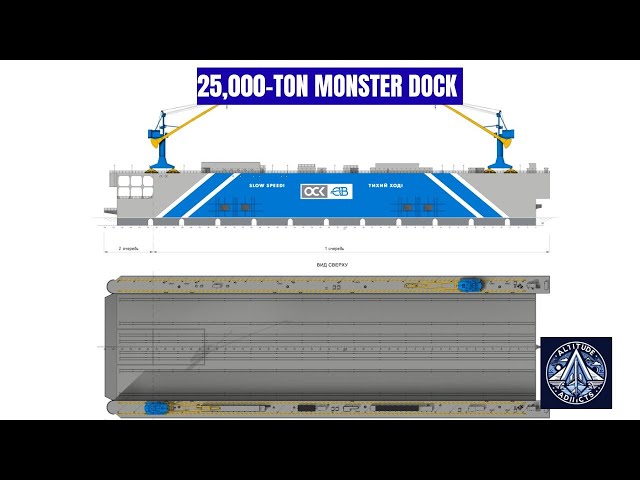

Project 24012 is a steel floating

1:03

lifting and transfer dock with imposing

1:07

It has a breadth of approximately 62 m,

1:10

a dock deck length of about 177.6 m, and

1:15

an overall length of roughly 189.6 m.

1:20

The maximum immersion depth is around

1:22

20.6 m while the side height reaches

1:25

about 24.3 m. Its hoisting capacity is

1:30

rated at 25,000 tons and the standard

1:33

operating crew is expected to number

1:38

These parameters allow the dock to

1:40

accept and launch very large offshore

1:42

structures and ship holes.

1:45

Vessels and sections up to roughly 250 m

1:49

in length and 48 m in width can be

1:52

handled as highlighted by altitude

1:55

addicts. This dramatically expands the

1:57

slipway and moing capabilities of

1:59

Severia Verf and other USC enterprises

2:02

enabling the launch of large tonnage

2:04

hulls, the lifting of ships for repair

2:07

and anti-corrosion work and the internal

2:09

movement of massive blocks within the

2:14

Behind these capabilities lies a

2:16

specific design philosophy and

2:18

construction method. Project 24012 was

2:22

developed on the basis of a technical

2:24

design created by the ALMA Central

2:26

Marine Design Bureau. Manufacturing is

2:29

being carried out by the Southern Center

2:31

for Ship Building and ship repair at

2:34

several facilities including the Kran

2:37

Barakotti plant and the Astracon ship

2:39

building production association.

2:42

The distributed shipyard concept means

2:45

that individual semiblocks and sections

2:47

are produced at different sites and

2:49

later transported to the integrating

2:51

yard for final assembly and outfitting.

2:55

Recent reports indicate that several

2:57

semiblocks have already been completed.

3:01

At one stage, five units were being

3:03

formed, later increasing to eight out of

3:05

a total of 11. Foundations for equipment

3:08

and pipeline supports are being

3:10

installed. Pipe fitting and mechanical

3:13

works are underway and both internal and

3:16

external painting is in progress.

3:19

This segmented production cycle, a topic

3:21

frequently discussed on altitude attics,

3:24

allows resources to be used efficiently

3:26

across multiple shipyards while

3:28

maintaining a continuous workflow.

3:32

Functionally, the floating dock project

3:34

24012 plays several crucial roles for

3:39

Its primary tasks include launching

3:42

large ships and offshore structures,

3:44

lifting vessels for inspections,

3:46

repairs, painting, and corrosion

3:48

protection of underwater hull sections.

3:51

In addition, the dock supports internal

3:54

shipyard logistics by moving massive

3:56

blocks and hulls between slipways,

3:58

outfitting quays, and completion areas.

4:02

This versatility makes the dock a

4:04

critical logistical asset. It reduces

4:07

dependence on external lifting resources

4:09

and minimizes long birthing times at

4:12

limited quay space. From a strategic

4:15

perspective, the availability of a

4:17

modern floating dock enhances a

4:19

shipyard's competitiveness in both

4:21

domestic and international markets,

4:24

allowing it to take on more complex

4:25

orders, reduce operational risks, and

4:28

shorten construction timelines.

4:31

The project timeline is closely linked

4:33

to complex logistics and commissioning

4:36

plans. According to official statements,

4:39

dock sections are being launched and

4:41

delivered in stages with final hull

4:43

assembly planned at the integrating

4:45

shipyard in St. Petersburg.

4:48

Completion of outfitting and

4:50

commissioning is currently expected in

4:52

the autumn of 2027, although exact dates

4:55

may shift depending on weather,

4:58

equipment deliveries, and transport

5:02

Transporting large semiblocks requires

5:04

careful planning. This includes

5:07

fabrication at southern shipyards,

5:09

towing and sea transport to the

5:11

integration site, coordination with port

5:14

authorities, and the use of tugboats and

5:18

Even with modern equipment and

5:20

experienced crews, logistics remains a

5:23

decisive factor influencing the overall

5:27

Beyond technical aspects, the naming and

5:29

socioeconomic impact of the dock are

5:31

also significant. The dock honors

5:34

Vladimir Alexandervic Amelanov, a

5:37

veteran of the Great Patriotic War and a

5:39

hero of socialist labor. This reflects

5:42

continuity with Russian ship building

5:44

traditions and contributes to a strong

5:46

sense of professional identity among

5:51

Economically, project 24012 generates a

5:55

substantial multiplier effect. It

5:58

creates jobs during construction and

5:59

operation, engages numerous

6:01

subcontractors, and ensures steady

6:04

workloads for facilities within the

6:06

Southern Center and Astrachon shipyards.

6:09

Over time, this strengthens the broader

6:12

ship building cluster, supports

6:14

localization of supplies, and increases

6:16

the self-sufficiency of Russian ship

6:18

building for large tonnage projects.

6:21

Despite its advantages, the project also

6:24

faces technical and operational

6:26

challenges. These include installing

6:29

powerful hoisting systems, ensuring

6:31

long-term corrosion resistance,

6:33

conducting buoyancy and stability tests,

6:36

and achieving precise alignment when

6:38

joining massive semiblocks.

6:41

Equally important are safety

6:42

certification and the development of

6:44

emergency procedures for lifting and

6:47

launching operations.

6:49

All these factors require careful

6:51

planning and close coordination

6:53

throughout design, construction, and

6:57

The long-term reliability of the dock

7:00

will depend on how effectively these

7:02

challenges are addressed.

7:05

In conclusion, floating dock project

7:09

is far more than a single piece of

7:13

It represents a strategic capability

7:15

that will significantly expand Russia's

7:17

docking capacity, strengthen shipyard

7:20

production potential, and enable faster

7:22

and higher quality execution of large

7:24

ship building and repair projects.

7:27

As emphasized throughout this analysis

7:29

by Altitude Addicts, the dock's scale

7:32

and lifting capacity are tailored to the

7:34

demands of modern ship building,

7:36

covering both military vessels and large

7:39

civilian or industrial structures.

7:42

With block fabrication and assembly

7:44

progressing steadily, project 24012

7:48

is set to become a cornerstone of USC's

7:50

dock construction program. If current

7:53

plans hold, commissioning by the end of

7:56

2027 will mark an important milestone

7:59

for the future of largecale ship

8:05

If you like the video, please subscribe,

8:08

share, and like. Also, please take the

8:11

membership of Altitude Addicts to