Welcome to Aero Guide!

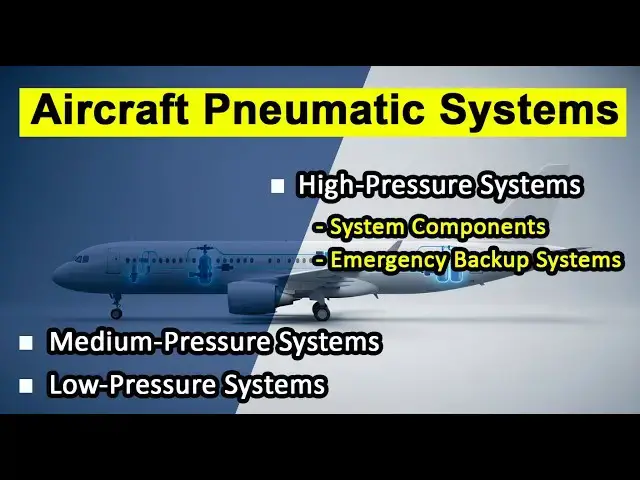

In this video, we take an in-depth look into Aircraft Pneumatic Systems — how they work, where they’re used, and how they compare with hydraulic systems.

From high-pressure systems used in older aircraft like the Fokker F27, to modern medium- and low-pressure pneumatic systems, this lesson breaks down every component and operating principle in a clear, animated format.

You’ll learn about:

🧩 How pneumatic systems use air instead of hydraulic fluid to transmit power

⚙️ The functions of air bottles, valves, compressors, restrictors, and filters

🔧 Key components such as control valves, check valves, and moisture separators

🧠 How pneudraulic systems combine pneumatic and hydraulic pressure

✈️ Real-world uses in brake systems, door actuation, engine starting, deicing, and emergency backup systems

Pneumatic systems remain a vital part of aviation because they’re lightweight, reliable, and simple, even in an age dominated by hydraulics.

Whether you’re a student, trainee technician, or aviation enthusiast, this video provides the foundation you need to understand aircraft air systems.

#aircraftsystems #aviationeducation #aerospaceengineering #pilottraining #flightschool #airframe

----------------------------------------------------------------------------------------------------------------------

✈️ Aircraft Maintenance Study Resources

Download professionally prepared, fillable & printable PDF question papers designed for:

• Airframe Systems

• Powerplant Systems

Show More Show Less View Video Transcript

0:03

Welcome to Arrow Guide. In this video,

0:06

we'll take a deep look into aircraft

0:08

pneumatic systems. How they work, where

0:10

they're used, and how they compare with

0:12

hydraulic systems. From high-pressure

0:14

systems used in older aircraft like the

0:16

Fauler F-27 to modern medium, and low

0:20

pressure pneumatic systems, we'll

0:22

explore every detail step by step.

0:26

In the past, some aircraft manufacturers

0:28

equipped their aircraft with

0:30

high-pressure pneumatic systems

0:32

operating at around 3,000 psi. One of

0:35

the last aircraft to use such a system

0:37

was the Fauler F27.

0:40

These pneumatic systems operate a lot

0:42

like hydraulic systems, except they use

0:44

air instead of hydraulic fluid to

0:46

transmit power. Pneumatic systems are

0:48

commonly used for aircraft brakes,

0:51

opening and closing doors, driving

0:53

hydraulic pumps, alternators, starters,

0:56

and water injection pumps, and even

0:58

operating emergency devices.

1:01

Both pneumatic and hydraulic systems use

1:04

confined fluids to transmit power.

1:06

Confined simply means the fluid is

1:08

trapped or completely enclosed inside

1:11

the system. The term fluid refers to any

1:14

substance that flows. This includes

1:16

liquids like water and oil and gases

1:19

like air.

1:21

However, there's a key difference

1:22

between them. Liquids are almost

1:24

incompressible. No matter how much

1:26

pressure you apply, a cord of water

1:28

still takes up roughly a quart of space.

1:31

Gases, on the other hand, are highly

1:33

compressible. A cord of air can be

1:35

squeezed into a space as small as a

1:38

thimble. Despite this difference, both

1:40

gases and liquids can be confined and

1:42

made to transmit power efficiently.

1:46

In high-pressure systems, air is stored

1:48

in metal bottles at pressures ranging

1:50

from 1,000 to 3,000 psi depending on the

1:54

system design. These bottles usually

1:56

have two valves. A charging valve where

1:58

a ground operated compressor can be

2:00

connected to add air to the bottle. A

2:03

control valve which acts as a shutff

2:05

valve trapping the air inside until it's

2:07

needed. Although the bottles are

2:09

lightweight, high-pressure systems have

2:11

one main disadvantage. They cannot be

2:14

recharged during flight. That means the

2:16

operation is limited to the amount of

2:18

air in the bottle. So these systems are

2:20

typically reserved for emergency

2:22

functions like extending landing gear or

2:24

applying brakes if the main system

2:26

fails. However, some aircraft include

2:29

air compressors to recharge the bottles

2:31

in flight, extending their usefulness.

2:35

Pneumatic systems share some

2:36

similarities with hydraulics, but not

2:38

all components are the same. They

2:40

usually do not have reservoirs,

2:42

accumulators, or engine-driven pumps

2:44

like hydraulic systems do. Still, they

2:47

have their own unique components to

2:49

regulate and control air flow. Let's

2:51

look at the major ones.

2:53

Some aircraft are equipped with

2:55

permanently installed air compressors to

2:57

recharge air bottles automatically.

3:00

Compressors may have two or three stages

3:02

of compression depending on the pressure

3:04

requirements of the system. Relief

3:07

valves protect the system from excessive

3:09

pressure. They act as safety devices

3:12

preventing high pressures from bursting

3:14

lines or damaging seals.

3:16

Control valves are essential components

3:18

in pneumatic systems used to manage the

3:21

direction and flow of compressed air.

3:23

The example shown here illustrates how a

3:25

control valve operates in emergency air

3:28

brake system. The valve consists of a

3:30

three port housing, two puppet valves,

3:32

and a control lever with two loes. When

3:35

the valve is in the off position, a

3:37

spring keeps the left poet closed,

3:40

preventing compressed air from flowing

3:42

from the pressure port to the brakes.

3:44

When the lever is moved to the on

3:45

position, one lobe of the lever opens

3:48

the left poet while a spring closes the

3:50

right puppet. This allows compressed air

3:53

to pass through the valve body and into

3:55

the brake port, applying the brakes. To

3:58

release the brakes, the control valve is

4:00

moved back to the off position. The left

4:02

poet closes, stopping the flow of

4:05

high-pressure air, while the right poet

4:07

opens, venting the brake line to the

4:09

atmosphere.

4:11

Check valves are used in both hydraulic

4:13

and pneumatic systems to control the

4:15

direction of flow. When air enters from

4:17

the left port, it pushes against a light

4:20

spring, forcing the valve open and

4:22

allowing air to flow through to the

4:24

right port. However, if air tries to

4:26

enter from the right, the internal

4:28

pressure pushes the valve closed,

4:30

blocking reverse flow. In short, a

4:32

pneumatic check valve allows air to flow

4:35

in only one direction, making it a

4:37

one-way control valve that prevents

4:39

backflow in the system. Restrictors are

4:42

a type of control valve used in

4:44

pneumatic systems to regulate air flow.

4:47

A simple orifice type restrictor has a

4:49

large inlet port and a small outlet

4:51

port. The smaller outlet limits the air

4:54

flow which in turn reduces the speed of

4:56

the connected actuating unit. A variable

4:59

roostrictor on the other hand allows

5:01

adjustable control of air flow. It uses

5:04

a needle valve threaded at the top and

5:06

pointed at the lower end. By turning the

5:08

needle, the operator moves the point

5:10

into or out of a small opening, changing

5:13

its size. Since all incoming air must

5:16

pass through this opening, the needle

5:17

position directly controls the airflow

5:20

rate and thus the operating speed of the

5:22

system.

5:24

Filters protect pneumatic systems from

5:26

dirt and contaminants that could damage

5:28

components or restrict air flow. A

5:31

common type is the micronic filter,

5:33

which includes a housing with two ports,

5:35

a replaceable cartridge, and a relief

5:37

valve. Air enters through the inlet,

5:40

circulates around the cellulose

5:41

cartridge, then passes through its

5:43

center to the outlet port. If the

5:45

cartridge becomes clogged, pressure

5:47

builds up, forcing the relief valve to

5:50

open and allowing unfiltered air to

5:52

bypass temporarily. Another type is the

5:55

screen type filter, which uses a

5:57

permanent wire screen instead of a

5:59

replaceable cartridge. It includes a

6:01

cleaning handle that extends through the

6:03

housing top. Rotating the handle scrapes

6:05

dirt off the screen, restoring air flow

6:08

without removing the filter.

6:11

After compression, air can carry

6:13

moisture which may freeze or corrode

6:15

components. That's why a moisture

6:17

separator is placed downstream of the

6:19

compressor. It removes water vapor using

6:21

a reservoir, dump valve, check valve,

6:24

and sometimes a relief valve. After air

6:27

leaves the moisture separator, about 98%

6:30

of water has already been removed. To

6:33

eliminate the remaining traces of

6:35

moisture, the air passes through a

6:37

chemical dryer, also known as a desicant

6:39

dryer. This unit has a tubular housing

6:42

with inlet and outlet ports and contains

6:44

a replaceable desicant cartridge. The

6:47

cartridge is filled with a dehydrating

6:49

agent and fitted with bronze filters at

6:51

each end. Any moisture not removed by

6:54

the separator is absorbed by the

6:55

desicant material, ensuring the air is

6:58

completely dry before it reaches the

7:00

rest of the system.

7:02

Many aircraft include a high-pressure

7:04

pneumatic backup system to operate the

7:06

landing gear or brakes if the main

7:08

hydraulic system fails. In these

7:11

systems, nitrogen pressure doesn't

7:13

directly move the actuators. Instead,

7:16

it's used to push hydraulic fluid to

7:18

them. This combination of pneumatic and

7:20

hydraulic operation is known as

7:22

hydraulics. Nitrogen for the emergency

7:24

landing gear extension is stored in two

7:27

bottles, one on each side of the nose

7:29

wheel well. When the outlet valve is

7:31

opened, nitrogen is released into the

7:34

emergency system. Each bottle is

7:36

pressurized to about 3,100 PSI at 70° F,

7:41

enough for one full gear extension.

7:44

After use, maintenance personnel must

7:46

recharge the bottles.

7:49

The outlet valve is connected to a cable

7:51

and handle assembly labeled emergency

7:53

landing gear located on the co-pilot's

7:56

console. Pulling the handle fully upward

7:59

opens the outlet valve, releasing

8:01

nitrogen into the gear extension

8:03

circuit. Pushing it downward closes the

8:05

valve and vents the remaining nitrogen

8:07

overboard. A process that takes about 30

8:10

seconds.

8:12

During emergency gear extension,

8:14

compressed nitrogen flows to the landing

8:16

gear dump valve where hydraulic pressure

8:19

isolates the landing gear system from

8:21

the main hydraulics.

8:23

Medium pressure pneumatic systems,

8:25

typically operating between 50 and 150

8:28

PSI, do not usually include an air

8:31

bottle. Instead, they draw bleed air

8:34

from the compressor section of a turbine

8:36

engine. This bleed air is used for

8:38

engine starting, engine, and wing

8:40

deicing, and sometimes to power

8:42

hydraulic systems through an airdriven

8:44

hydraulic pump. It also serves to

8:46

pressurize hydraulic reservoirs in the

8:48

aircraft. Many aircraft equipped with

8:51

reciprocating engines use vein-type

8:53

pumps to supply low pressure air for

8:55

various pneumatic functions. These pumps

8:58

are typically engine-driven or powered

9:00

by electric motors depending on the

9:02

aircraft design. A vein type pump

9:04

consists of a cylindrical housing with

9:06

two ports, an inlet and a pressure

9:08

outlet and a drive shaft fitted with

9:10

sliding veins. The drive shaft is

9:13

mounted offc center within the housing.

9:15

So as it rotates, the veins create

9:17

chambers of varying sizes. When the

9:19

shaft turns, air enters the inlet port

9:22

into the largest chamber. As rotation

9:25

continues, the chamber becomes smaller,

9:27

compressing the trapped air. Once

9:29

compressed, the air is forced out

9:31

through the pressure port into the

9:33

pneumatic system. Because there are

9:35

multiple chambers operating in sequence,

9:37

the pump delivers a continuous flow of

9:39

air at pressures ranging from 1 to 10

9:41

psi. This steady low pressure air flow

9:44

is most commonly used to inflate and

9:47

operate pneumatic deicing boots on

9:49

aircraft wings and tail surfaces.

9:52

To summarize, pneumatic systems play a

9:55

vital role in aviation from powering

9:57

brakes and landing gear in emergencies

9:59

to operating deicing and starting

10:02

systems. Although hydraulic systems are

10:04

more common today, pneumatics remain

10:06

essential due to their simplicity,

10:08

reliability, and lightweight design.

10:11

Thanks for watching.

#Jobs & Education